Strapping Machine Case Study: Real Results From Streamlined Operations

Strapping Machine Case Study: Real Results From Streamlined Operations

Blog Article

How a Strapping Maker Can Enhance Your Storage Facility Efficiency

In today's fast-paced warehousing environment, effectiveness is key. Strapping Machine. You could discover that automating your strapping procedure can dramatically streamline procedures. With the ideal maker, you can reduce labor expenses and lessen plan damages during transit. Not all strapping equipments are developed equal. Comprehending what to look for and how to incorporate these machines right into your existing process is important for maximizing their benefits. Let's explore what makes a strapping maker a crucial device for your storage facility

The Role of Strapping Machines in Modern Warehousing

In today's busy warehousing environment, strapping machines play a vital duty in boosting performance and productivity. You depend on these equipments to secure plans snugly, lowering the threat of damage during transit. As opposed to by hand covering and strapping products, you can utilize computerized remedies that conserve time and decrease labor costs.Strapping machines aid enhance your operations by accelerating the packing process. They ensure uniformity in just how items are packed, allowing you to maintain high requirements in packaging. You'll locate that utilizing a strapping equipment lessens the requirement for extra products, therefore enhancing your supply chain.Moreover, these devices are adaptable to different package shapes and sizes, making them versatile tools in your storehouse. By incorporating strapping makers into your procedures, you'll not only enhance effectiveness but additionally create a more well organized and efficient workplace, allowing your team to concentrate on core tasks.

Benefits of Automating the Strapping Refine

Automating the strapping procedure not just conserves time yet additionally greatly increases your stockroom's general efficiency. By getting rid of hands-on strapping, you minimize labor prices and lessen the danger of human mistake. This means your group can concentrate on even more important tasks, boosting workflow efficiency.Additionally, automated strapping makers consistently apply the ideal stress and protected plans much more dependably, making sure that your products are well-protected throughout transportation. You'll observe less damaged products, which can result in lowered returns and enhanced customer satisfaction.Moreover, automating this procedure permits faster throughput, suggesting you can deliver more orders in much less time. This agility can give you a competitive side in today's hectic market. Overall, purchasing automated strapping improves your operations, boosts precision, and can ultimately cause higher success for your stockroom. Embrace this innovation and watch your efficiency skyrocket.

Secret Features to Look for in a Strapping Machine

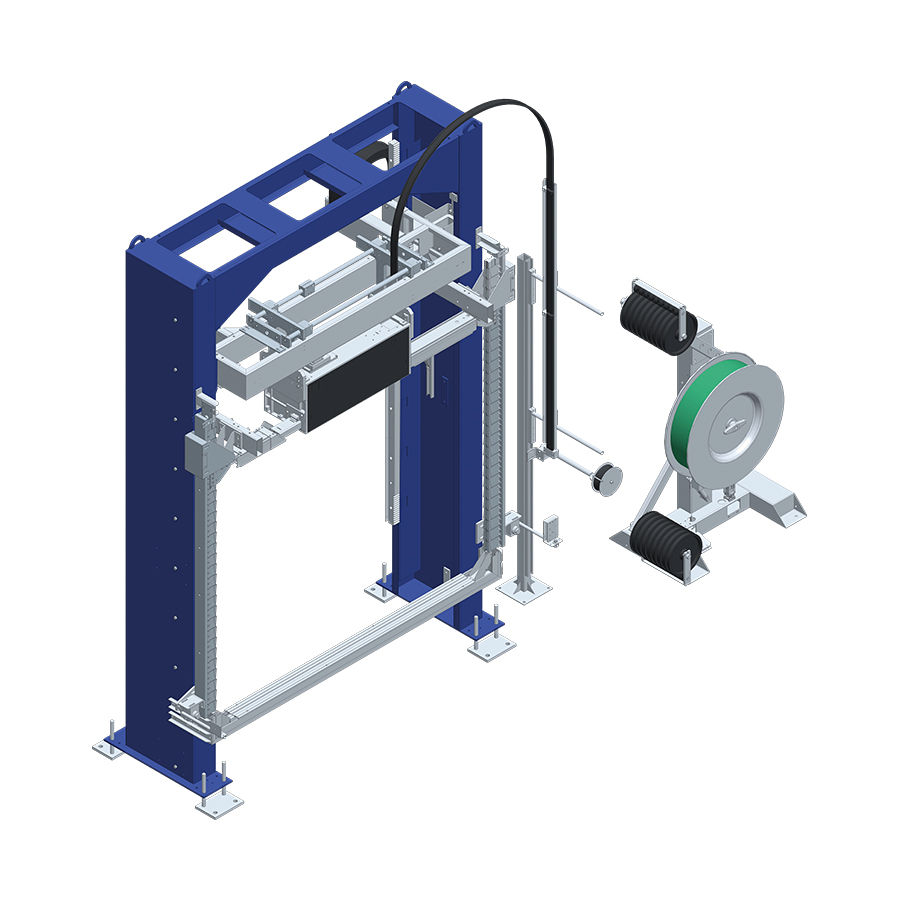

Kinds Of Strapping Machines and Their Applications

Strapping equipments can be found in various types, each made to meet details functional demands in a storage facility. Semi-automatic strapping makers permit you to by hand feed the strap while the machine does the reducing and sealing. This is perfect for reduced volume procedures where versatility is essential. After that there are completely automatic equipments, ideal for high-speed environments. They immediately feed, stress, and seal straps, improving effectiveness markedly.Another option is handheld strapping devices, which provide flexibility and simplicity for tiny jobs or limited spaces. If you handle hefty loads, take into consideration a heavy-duty strapping maker designed to take care of larger products safely. Electrical strapping equipments offer constant stress for consistent outcomes, making them a fantastic choice for high quality control. By recognizing the different types, you can choose the ideal strapping machine that lines up with your storage facility's particular requirements, enhancing overall efficiency.

Incorporating Strapping Equipments Into Existing Workflow

Integrating strapping devices right into your existing process can greatly improve and simplify procedures performance. Beginning by reviewing your existing product packaging process to identify bottlenecks. Determine where strapping can add worth, whether it's safeguarding boxes for delivery or packing items for storage.Next, choose the best sort of strapping device that fits effortlessly into your configuration. See to it it works with your packaging products and can manage your quantity demands. Educating your staff is important; they need to recognize just how to run the machine efficiently and safely.Consider positioning the strapping equipment near to packing stations to reduce motion. In this manner, you'll reduce time invested in product packaging tasks. Keep an eye on the combination process and collect feedback from your group. Change as needed to maximize performance. By thoughtfully including strapping devices, you'll enhance your process, decrease labor prices, and eventually improve general storehouse performance.

Situation Studies: Success Stories From Stockrooms

Effective warehouses usually share stories of just how strapping devices changed their operations. As an example, a large warehouse dealt with delays during peak periods due to hands-on strapping methods. click site After presenting a totally automated strapping device, they saw a 30% rise in product packaging speed. Orders that when took hours to prepare were currently completed in minutes, permitting faster delivery and improved client satisfaction.Another stockroom dealing with ecommerce experienced constant item damage during transportation. By implementing a strapping maker, they safeguarded plans much more properly, decreasing damages prices by 40%. This not just conserved prices on replacements however additionally boosted their credibility for reliability.In both situations, the intro of strapping machines streamlined process and enhanced effectiveness. You can see just how these success stories illustrate the concrete benefits of upgrading your storehouse procedures. Embracing this technology could be the key to releasing your storage look at here facility's complete possibility.

Future Fads in Strapping Modern Technology and Stockroom Performance

As you look in advance, consider how automation and robotics are reshaping strapping technology in storage facilities. You're likely to see a change in the direction of lasting products and clever technology that improves effectiveness. Embracing these trends can considerably improve your operational productivity and environmental influence.

Automation and Robotics Assimilation

Lasting Strapping Products

The promote greater effectiveness in stockrooms goes hand in hand with an expanding concentrate on sustainability, particularly when it pertains to strapping products. You can improve your procedures by choosing green options like eco-friendly polyesters or recycled polypropylene - Strapping Machine. These products not only decrease your ecological impact yet also preserve toughness and integrity. By adopting sustainable strapping, you show your commitment to environment-friendly techniques, which can improve your brand picture and draw in ecologically mindful clients. Furthermore, numerous providers are currently using cutting-edge choices that incorporate resilience with sustainability, ensuring you don't sacrifice performance. Changing to these materials can result in cost savings as well, offered their possibility for lowering waste and boosting recyclability in click over here your supply chain

Smart Technology Advancements

With developments in smart technology, strapping machines are coming to be extra straightforward and effective than ever. You'll find attributes like real-time tracking and automated modifications that help streamline your procedures. These makers can now incorporate with storehouse administration systems, enabling for better supply tracking and reduced mistakes. Envision having the ability to track each band's stress and quality immediately, ensuring peak performance without manual checks. Furthermore, predictive analytics can forecast upkeep requirements, reducing downtime. As you embrace these technologies, you'll not only boost performance however likewise enhance work environment safety. Purchasing smart strapping modern technology is a wise selection for future-proofing your storage facility and remaining competitive in an ever-evolving market. Welcome the change, and enjoy your efficiency skyrocket!

Regularly Asked Questions

What Is the Typical Life-span of a Strapping Device?

The typical lifespan of a strapping device typically ranges from 5 to ten years, relying on usage and maintenance. Routine treatment can expand its life, ensuring you get one of the most worth from your financial investment.

How Much Upkeep Do Strapping Devices Need?

Strapping makers call for normal upkeep to guarantee peak efficiency. You should examine elements often, tidy the maker, and change used parts as required. Following the producer's standards will assist you decrease downtime and prolong the machine's lifespan.

Can Strapping Machines Deal With Different Strap Sizes?

Yes, strapping makers can deal with different strap sizes. You just require to change the setups or pick a machine designed for adaptability. This versatility assists you effectively manage various packaging demands in your operations.

Are Strapping Devices Energy-Efficient?

Yes, strapping machines can be energy-efficient. They usually make use of much less power than hand-operated approaches, lowering general energy consumption. By choosing the appropriate design, you'll save energy and reduced expenses while preserving productivity in your procedures.

What Safety And Security Features Should Strapping Machines Include?

When choosing a strapping equipment, you need to try to find features like emergency situation quit buttons, security guards, and automatic stress modifications. These improvements aid safeguard operators and keep a risk-free workplace in your storehouse. You'll find that utilizing a strapping equipment lessens the demand for additional products, consequently enhancing your supply chain.Moreover, these machines are versatile to various bundle sizes and forms, making them versatile devices in your storage facility. When selecting a strapping maker, it's vital to take into account a number of key attributes that can considerably affect your storage facility procedures. Semi-automatic strapping devices permit you to manually feed the strap while the machine does the sealing and reducing. Educating your staff is necessary; they require to comprehend just how to operate the maker successfully and safely.Consider placing the strapping maker close to packaging stations to lessen activity. Successful storehouses often share stories of exactly how strapping makers transformed their operations.

Report this page